Background

In 1995, one of our largest customers challenged us to design and build the largest traction thickener possible that would still be economically and practically feasible. In response, we developed a peripheral traction thickener of 125m-diameter, with a duty-rated torque (DRT) of 8 M lb-ft and our proprietary FLSmidth E-DUC® auto-dilution system.Once in operation, this thickener and the feed dilution system proved to work so well that it processed 40% of the total tailings produced by the plant, while the remaining 60% was processed by four older thickeners of the same diameter

| Startup 1999 | ||||||

|---|---|---|---|---|---|---|

| High-rate with E-DUC® | ||||||

| 2,050 tph @ 50-55% solids | ||||||

| Slope | 1¼ 2½ : 12 | |||||

| Centre depth | 11,870mm | |||||

| Vol. approx. | 564,040m3 | |||||

| Torque | Drive | Rakes | ||||

| lb-ft | 10 M | 20 M | ||||

| N-m | 13.5 M | 27.1 M | ||||

The challenge expands

As a result of this success, between 1997 and 2001

the same customer requested we design the same

thickener, but with an increased DRT. In response, we

offered a 125m-diameter thickener with a peripheral

traction drive providing 10 M lb-ft of torque. Due to the

customer’s concerns that the high DRT could potentially

damage the rake mechanism, the request included that

the mechanism be designed for twice the rated torque

of the drive.

The outcome of this exercise was that we designed and built three thickeners of 125m-diameter, all with E-DUC auto dilution systems and 10 M lb-ft peripheral traction drives, but with rakes designed for 20 M lb-ft.

More than a decade later, with continued successful operation of these three thickeners, the same customer expanded its operation, and again selected FLSmidth to supply an additional three thickeners of the same size and design to augment production capacity.

| Startup 2021 | ||||||

|---|---|---|---|---|---|---|

| High-rate with E-DUC® | ||||||

| 2,050 tph @ 50-60% solids | ||||||

| Slope | 2½ : 12 | |||||

| Centre depth | 11,870mm | |||||

| Vol. approx. | 90,000m3 | |||||

| Torque | Drive | Rakes | ||||

| lb-ft | 10 M | 20 M | ||||

| N-m | 13.5 M | 27.1 M | ||||

New challenges, new solutions

As these upgraded thickeners continued to operate

and perform well over the years, another large

copper-producing customer requested we provide a

similar thickener design, but for a more complex type of

copper tailings. In response to this request, we built a

125m-diameter thickener, with a 10 M lb-ft peripheral

traction drive and 20 M lb-ft mechanism design — but

in this case, with our proprietary P-DUC forced/pumped

dilution system. The pumped dilution relied on four

operating P-DUC pumps to achieve the high dilution

flowrates. In addition, we increased the slope of the

tank floor. The thickener system demonstrated great

efficiency in consistently achieving pulp dilution to a

relatively low solids concentration in the thickener feedwell, which improved the flocculation and settling/sedimentation rate. We later constructed a second of

these thickener systems, due to the customer’s

plant expansion.

Then this customer recently requested a third thickener of the same type and diameter, we were challenged once again to take our design to the next level. Our response was to engineer and build a thickener that will achieve underflow densities at the limits between high rate and high density. It features a floor slope that is typically used in high-density thickeners (3:12), which gives it a depth of almost 20m in the centre. Again, the thickener has a diameter of 125m, an installed torque of 10 M lb-ft and rake mechanism of 20 M lb-ft. It uses the forced-dilution P-DUC system, and is designed to process 3,750 tph of tailings. In this case, due to increased capacity and the requirement to have complete redundancy of the P-DUCs (operating and standby), the P-DUCs were required to be designed to pump more than double the previous dilution flowrates.

Ongoing advancements

The relatively new development of high-density and paste thickeners, combined with the need to process ever-increasing tonnages on projects, has led us to improve our thickening technology using a variety of considerations. An extremely important factor in our technology is the torque capacity of the drives, especially with increased thickener diameters, which subsequently increases the required or installed torque.While peripheral traction drives for large-size thickeners were the first to reach a torque of 10 M lbft of DRT, these drives are not always ideally suited to the application or thickener configuration, especially where the intent is to use multiple thickeners of the same size and with elevated steel tanks.

In response to the needs being dictated by the market, we developed the C140 series of centre (column/cage) drives, where we use up to six (6) sprockets/pinions (C140P-6), with the original intention of reaching a torque of 10 M lb-ft – equivalent to the traditional traction drive.

The 20 M lb-ft rake design in the peripheral traction thickeners has allowed us to develop and gain the necessary experience to design and manufacture robust mechanisms that can easily handle a drive torque of 10 M lb-ft – and significantly higher – for the rake arms, etc., as was proven with our 20 M lb-ft design.

As part of the continuous development process over the past three years, and in order to not only meet their needs but also contribute to increasing productivity for our customers, our R&D engineers have used finite element analysis (FEA) and have applied the use of new materials to modify and improve the design of our C140P-6 centre drive with 10 M lb-ft of duty-rated torque. The newly launched C140P-6-SD (super-duty) drive is designed for a DRT of 12 M lb-ft, (16.2 M N-m). This drive has the highest torque on the market, and it is capable of achieving our customers’ continuously increasing demands.

| Startup 2013 | ||||||

|---|---|---|---|---|---|---|

| High-rate with E-DUC® | ||||||

| 6,800 m3/h | ||||||

| Slope | 3 : 12 | |||||

| Centre depth | 13,950mm | |||||

| Vol. approx. | 35,500m3 | |||||

| Torque | Drive | Rakes | ||||

| lb-ft | 8.3 M | 8.3 M | ||||

| N-m | 11.2 M | 11.2 M | ||||

Additional improvements

In addition to drive developments, we also have considered the ability of the thickener raking mechanisms to move and discharge higher yield-stress material, leading to new design efforts in developing low-drag rake arms that have proven critical to discharging high underflow densities. Rake replacement projects have shown that high-strength tubular rake construction can enable an increase in underflow density of 2 to 3 wt%, compared with traditional box-truss construction.More recently, for very high-tonnage projects with a yield-stress discharge, we have developed a spiral inner rake blade design to greatly improve mud raking and discharge in the critical zone near the discharge drum of the thickener.

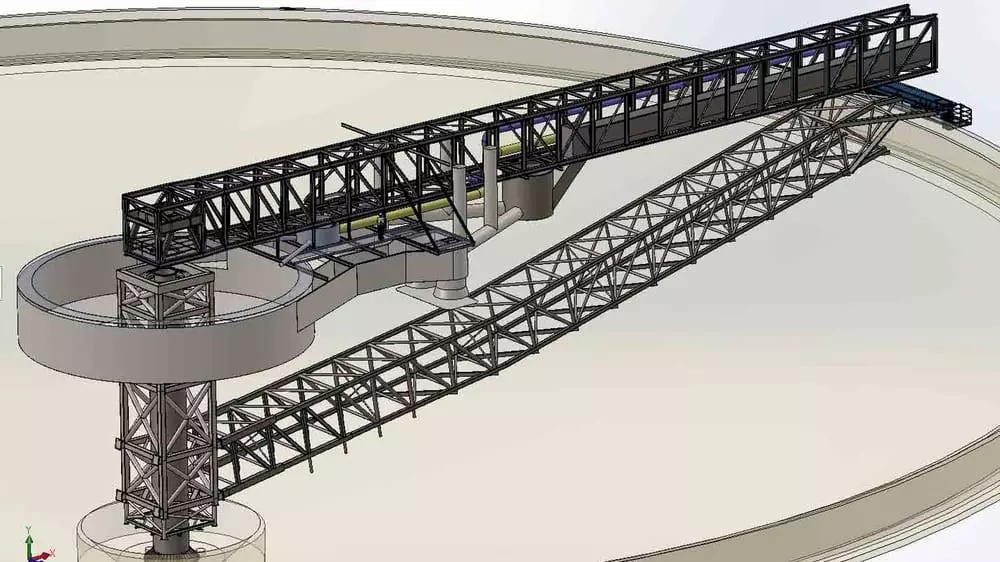

These spiral rake blades are a specific design feature on three 45m-diameter FLSmidth deep-cone paste thickeners currently being erected on a project in Kazakhstan. A view of the general configuration is above. Computational fluid dynamics (CFD) modelling shows this design reduces short circuiting and improves the mud bed residence time distribution.

An eye towards the future

With all of these developments over the past 25 years,

we have proven we can design and build the most robust

and highest-performance high-density and paste thickeners

on the market. As a core value, FLSmidth aims to improve the

productivity of the mining business as a whole, and in line

with this we continue to develop our thickening technology

to meet the needs being expressed by our customers.

High-density and paste thickening recovers substantially

more water than other thickening methods, while still

allowing the tailings to be pumped and distributed easily

into the tailings storage facility. Maximising the density at

the deposit minimises the volume required for storage.

Over the last three years, we have continued to engineer

and supply large-diameter tailings thickeners into copper

projects in South America, including the following high-rate

(HRT), high-density (HDT) & deep-cone thickeners (DCT)

under construction as of Q4 2020:

- 100m HRT

- 120m and (2) 85m HRTs

- 125m HDT

- 43m DCT

Other copper tailings projects in the same timespan include (2) 125m HRTs in China and (3) 45m DCTs in Kazakhstan.